Winter came but even those who do not use coal, oil or gas for heating needn’t worry.

According to the Institute for Energy Research, demand for fossil fuels, and especially gas, has skyrocketed in 2018, triggering a consequent increase in carbon dioxide emissions, despite the significant share of renewables in the planet’s energy mix.

The unexpectedly increased demand for energy is attributed, among other things, to weather conditions that have forced populations from different parts of the world to rely more on heating and cooling the premises. Coal, oil and gas certainly have their eco-friendly alternatives for heating the space during the winter days – and at the same time its cooling during the summer.

Even though it is said that love can warm you up and also cool you down, when we want to reconcile reaching the optimum temperature and reducing harmful emissions – it is not an effective solution. Heat pumps, on the other hand, are an excellent option for customers who want to save their financial resources and save the environment of negative impact. They operate on the principle of “reverse refrigerator” and “extract” the accumulated heat from the air, groundwater or soil and increase it.

In this way, a large amount of relatively low–temperature energy becomes high–temperature energy.

Types of heat pumps and the principle of operation

Depending on which of Earth’s unlimited “free” energy sources they use, heat pumps are divided into:

- air–water;

- water–water;

- ground–water.

They all operate on the same principle of heat transfer from one place to another.

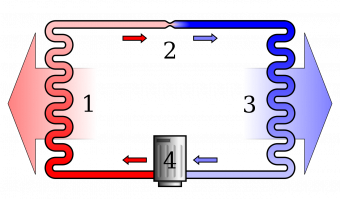

The main parts of heat pumps are evaporator, compressor, condenser and expansion valve.

Liquid gas enters the evaporator (3), where it evaporates in contact with outside temperatures. Then, in the form of gas, comes to the compressor (4) which compresses the it, thereby heating it to a temperature of up to 65 ° C. The gas then goes to the condenser (1) where it becomes liquid again and transfers heat through the exchanger to the heating water, then to the expansion valve (2) and the cycle starts over.