Feeding 10 billion mouths in 2050 poses a big challenge for the food industry. Doing that while also reducing carbon emissions enough to save the planet on which we depend for our food is another.

As the world grapples with COVID-19, hunger is getting worse. Food insecurity already impacts more than 2 billion people, while nearly 690 million people are hungry – an increase of 10 million from 2019, according to the UN’s Food and Agriculture Organization (FAO), which is marking World Food Day on 16 October.

It estimates the COVID-19 pandemic could add up to 132 million people to this number, depending on the economic growth scenario.

“Our future food systems need to provide affordable and healthy diets for all and decent livelihoods for food system workers, while preserving natural resources and biodiversity and tackling challenges such as climate change,” says the FAO.

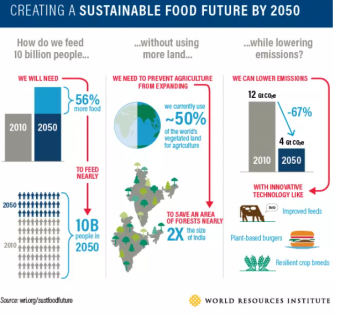

For those in the world who enjoy relative food security, appetite for meat is set to grow. Global demand for beef and other ruminant meats could rise by 88 percentage between 2010 to 2050, according to a World Resources Institute analysis of FAO data.

This would mean needing extra pastureland the size of India to feed livestock, it estimates, and the deforestation that would entail would put an end to the goal of limiting global temperature rises to 1.5°C. And that’s before taking into account emissions from the animals themselves.

As the world looks to reset its economy, along with food systems, in a cleaner way post-pandemic, one more sustainable solution coming to fruition is cultured meat.

What is cultured meat?

The process of growing meat in a laboratory involves taking stem cells from a live animal and growing them in nutrient-rich conditions.

For example, a small biopsy of skeletal muscle is taken from a cow, from which the stem cells are isolated and grown in a bioreactor with cell culture media.

The cells are split into several cell types including muscle and fat cells. This biomass is then processed to form the edible final product.

Although it sounds complicated, cultured meat takes much less time to grow, uses fewer of the planet’s resources, and no animals are slaughtered.

It’s still going to be a while until we see cultured meat, aka cell-based meat, on the menu, but start-ups have been working on it for five years. They’re progressing fast and the industry is big business.

In June 2019, Israeli start-up Aleph Farms claimed to be the first company to have developed steak in a lab. It hopes to trial the steak in high-end restaurants in the United States, Europe and Asia in 2021, with an official launch in restaurants and supermarkets in 2023.

Shiok Meats, based in Singapore, was founded in 2018 by two stem cell scientists, and the company says its patent-pending technology can grow crustaceans four times faster than the conventional method.

This year, it announced a $12.6 million Series A funding round, with a view to produce frozen cell-based shrimp meat for dumplings and other products in the coming years.

What are the challenges?

To scale up production of cultured meat and reduce costs, there are several technological challenges facing companies – and these are something the global life science and healthcare company Merck is working to overcome.

“As a leading supplier to the biopharma industry, we have extensive knowledge of the relevant science and biotechnology required for the production of cultured meat,” says Isabel de Paoli, Chief Strategy Officer at Merck.

“By working with companies that want to commercialize cell-based meat, we offer our knowledge and production skills to help them to overcome critical technological challenges.”

What are the key technological challenges that start-up companies are facing?

Cell line development

A cell grown in a culture is known as a cell line. Specific, food-grade meat producer cell lines are needed that are genetically stable; capable of differentiation and optimized for large-scale production.

More:

Bioreactors and bioprocessing

Bioreactors, bioprocess design and automation platforms are needed that enable growth and differentiation of multiple cell types simultaneously.

Edible scaffolds

Technologies similar to tissue engineering and regenerative medicine are needed to enable the next generation of structured products such as biodegradable, edible scaffolds/biomaterials and 3D cell culture processes.

Cell culture media

Cell culture media is currently estimated to account for 55 percentage to up to over 95 percentage of the product’s marginal costs. To produce cultured meat at scale, cell culture media needs to be much cheaper, suitable for efficient growth and differentiation of specific cell types, and free of any animal-derived material.

“We are tackling exactly these challenges and aim to design and commercialize serum-free media formulations to enable the efficient production of various cultured seafood, avian and mammalian species,” says Lavanya Anandan, Merck’s Head of Partnerships & External Innovation, at the company’s Silicon Valley Innovation Hub.

As these challenges are overcome, the cost of producing cultured meat will come down. The World Economic Forum’s white paper on Alternative Proteins from its Meat: The Future series, reports costs have already reduced dramatically over the past few years, from estimates of hundreds of thousands of dollars per kilo to $25.

Will people want to eat lab-grown meat?

But even if the cost comes down, there’s still a question of demand. Will people necessarily want to eat something they know has been grown in a lab, rather than a field?

Australia’s Generation Z seems to think not. The majority (72 percentage) of young adults surveyed in Sydney were not ready to accept cultured meat, although many thought it was a viable idea because of the need to transition to more sustainable food options and improve animal welfare.

Almost a third of them (28 percentage) were at least prepared to try it.

The perception of cultured meat is acknowledged by the industry, with not-for-profit The Good Food Institute running an Alt. Protein Project aimed at encouraging students – the leaders of tomorrow – to help change the food system.

It also recognizes the cultured meat industry has a literal image problem: Max Elder, former Research Director of the Food Futures Lab at Institute for the Future, says: “Images in popular media of cultured meat today look sterile, scientific, unappetizing; something to touch with a rubber glove or eat out of a petri dish.

“We need images of cultured meat that appear familiar and delicious, otherwise consumers will think the opposite before products even reach their plates.”

A study in PLOS ONE found that when framed positively and when people have favourable tasting experiences “acceptance of cultured meat is potentially high”. It also found that the perceived benefits of the meat could translate to a willingness to pay a premium price.

While the signs are promising, for now, it seems there are few technological and marketing hurdles to overcome before cultured meat will be feeding people – at scale – in future.

Source: World Economic Forum