Nowadays, the construction industry must progress rapidly to follow world trends. Constructors and manufacturers of construction machines are constantly working on improving technical capabilities to meet all the requirements in modern facilities construction. This industry is facing significant challenges since it is necessary to protect the environment by reducing non-renewable natural resources. However, the greatest attention is paid to technologies that will enable removing harmful construction materials from use.

Whenever someone mentions construction, the first association is mainly concrete. It is the most commonly used artificial material in the world whose production requires a large amount of energy and is a significant environmental pollution source.

Construction waste generated by the construction and demolition of existing buildings is at the very top of today’s biggest environmental problems. Currently, there is no solution to the ecological disposal of this waste. It is dumped in landfills. With the increase in the number and size of landfills, most often wild, arable land is almost irretrievably lost. It is precisely why the construction industry representatives focus on reducing energy consumption and the level of pollution and finding ways to reuse old concrete.

Developed countries have been working for years on programs and laws that reduce the relentless depletion of natural resources. Through various projects, they encourage recycling, development of alternative technologies and the use of secondary raw materials. Creating objects using the 3D printing method is a landmark when it comes to construction.

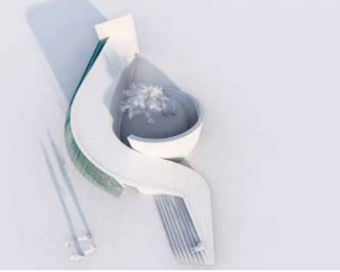

The development of technology in the 21st century surpasses perhaps the boldest forecasts because it sounds almost unbelievable that we will forget about traditional ways of building in the near future. This new way of building is a method of 3D printing of buildings that shortens construction deadlines, reduces the cost of production, and thanks to precise drawings and calculations, and there is simply no construction waste. You read that right – there is no waste. Add to that the fact that a special mixture that does not emit harmful gases is used in the construction of buildings using this method, and we can freely say that these are projects of the future. And while the news about innovative technologies mostly comes from abroad, the exception that confirms the rule comes to us from Čačak.

In focus:

The invention of Nikola Rakić from the company Natura Eco is a CNC machine that will be able to print a concrete object of 100 square meters in an incredible 15 hours. This young man became interested in construction very early, and numerous unfinished houses drew his attention throughout Serbia. He says that he has started thinking about how to help those who do not have enough funds to make ends meet since then.

“I have always been interested in artificial intelligence, programming languages and robotics, so I decided to learn more about the 3D printer systems themselves, which include G-code, automation, mechanics, etc. I am not an expert, but I work every day to widen my knowledge. I am currently committed to advancing and developing the largest CNC machine in the Balkans that has advanced software. With its help, we will have the opportunity to print each segment of a given object and also much more than that. Solutions for the extruder will provide both greater efficiency and a greater degree of automation of the printing process of the object”, explains our interlocutor.

According to the given design and recipe of a wellknown French company (which meets all ISO standards for the mixtures used for construction), the machine can print all the desired objects. Experts from Natura Eco are working to make all their machines powered by green energy because they believe that this is the only real way to justify their name. Together with experts in this field, they are developing a solution for a special mixture in which cement would not be used, since the process of obtaining it has a detrimental effect on the environment. The production of one ton of cement leads to the emission of one ton of carbon dioxide (CO2).

Text prepared by: Milica Radičević

Read the whole text in the new issue of the Energy portal Magazine SMART CITIES, december 2020 – february 2021.