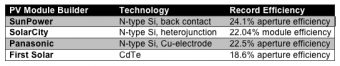

SunPower once again holds the record for the world’s most efficient rooftop solar module, achieving an NREL-validated 24.1 percent. NREL scientist Keith Emery, manager of the PV cell and module performance laboratory, provided the verdict in a release: “The module measured 11310.1 cm2 (aperture area) and had a power of 272.5 watts. We recorded 24.1 percent efficiency, which is a new record for silicon module efficiency.”

SunPower once again holds the record for the world’s most efficient rooftop solar module, achieving an NREL-validated 24.1 percent. NREL scientist Keith Emery, manager of the PV cell and module performance laboratory, provided the verdict in a release: “The module measured 11310.1 cm2 (aperture area) and had a power of 272.5 watts. We recorded 24.1 percent efficiency, which is a new record for silicon module efficiency.”

The record SunPower module was made “using laboratory solar cells of 25 percent mean efficiency” and is based on its commercially available module architecture. In February, NREL verified that a SunPower production panel had hit 22.8 percent efficiency.

Late last year, SolarCity made the claim that solar panels coming off of its 100-megawatt Silevo pilot production line were setting world records for solar module efficiency as “the world’s most efficient rooftop solar panel, with a module efficiency exceeding 22 percent.” A week later, Panasonic claimed the crown at 22.5 percent module efficiency.

An updated chart might help clear things up.

As covered in PV Magazine, Panasonic held the record for a while, with a 22.5 percent conversion efficiency verified by Japan’s National Institute of Advanced Industrial Science and Technology -which “builds upon the 25.6% efficiency record the company set in 2014 at cell level.”

When we reported on Solar City’s record panel claim late last year, it boasted an oddly precise 22.04 percent module-level efficiency as measured by the Renewable Energy Test Center (not a designated test facility). The silicon-based bifacial PV cell combines n-type substrates, copper electrodes, thin-film passivation layers, and a tunneling oxide layer that yields high conversion efficiencies. At the time, SolarCity claimed that its module would be “the highest-volume solar panel manufactured in the Western Hemisphere.” The record panel was manufactured on the company’s 100-megawatt pilot production line – its Buffalo factory won’t be at full production until 2017, with a target of 10,000 solar panels per day at full capacity. How the proposed acquisition of Solar City by Tesla will impact the new module factory remains uncertain.

Source: www.greentechmedia.com

On Thursday, the 23rd of June, Bertrand Piccard and Solar Impulse successfully made a historic, zero-fuel flight across the Atlantic, from New York to Seville, Spain.

On Thursday, the 23rd of June, Bertrand Piccard and Solar Impulse successfully made a historic, zero-fuel flight across the Atlantic, from New York to Seville, Spain.

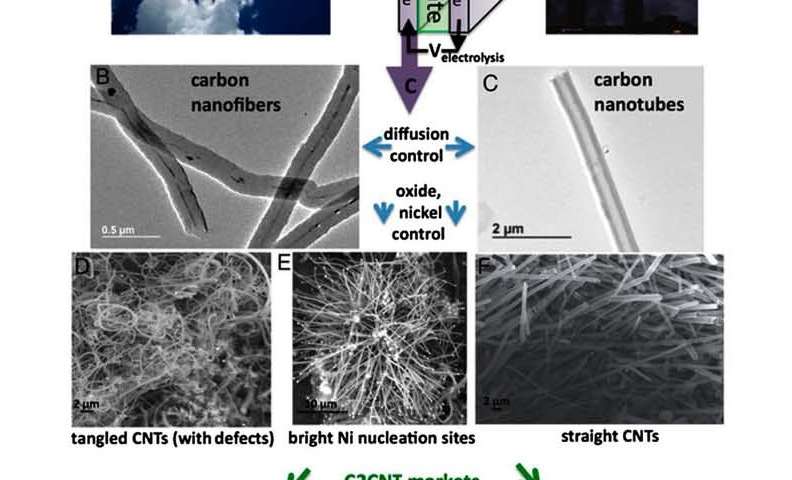

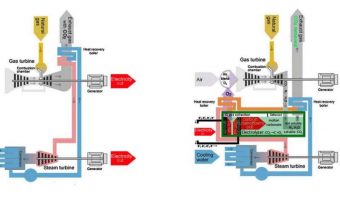

Last year, researchers at George Washington University proposed a method for transforming CO2 emissions into carbon nanotubes (CNTs). When applied to power plants, the technology could completely eliminate the power plants’ CO2 emissions while simultaneously producing a valuable product that is used for a variety of applications, including batteries, consumer electronics, airplanes, and athletic equipment. The technology can work with almost any kind of power plant, but the researchers specifically investigated its application for combined cycle (CC) natural gas power plants, which are the most efficient kind of electrical power plant yet still emit massive amounts of CO2.

Last year, researchers at George Washington University proposed a method for transforming CO2 emissions into carbon nanotubes (CNTs). When applied to power plants, the technology could completely eliminate the power plants’ CO2 emissions while simultaneously producing a valuable product that is used for a variety of applications, including batteries, consumer electronics, airplanes, and athletic equipment. The technology can work with almost any kind of power plant, but the researchers specifically investigated its application for combined cycle (CC) natural gas power plants, which are the most efficient kind of electrical power plant yet still emit massive amounts of CO2. In other words, the small decrease in power output is more than compensated for by the highly valuable carbon nano fibers and nano tubes that could be produced. This is mainly because industrial-grade carbon nano tubes are such an expensive commodity, which currently cost about $300,000/ton ($130/pound) to produce using methods available today. Using the new method, the researchers estimate that it would cost just $2,000/ton to produce CNTs—less than 1% of current production costs. The researchers hope that this large profit potential will make the technology seem like an obvious choice. Since CNTs are about 10,000 times more valuable than carbon tax credits (which are roughly $30/ton), the researchers predict that CNT production will offer a greater incentive for the energy industry to reduce carbon emissions than carbon tax credits offer.

In other words, the small decrease in power output is more than compensated for by the highly valuable carbon nano fibers and nano tubes that could be produced. This is mainly because industrial-grade carbon nano tubes are such an expensive commodity, which currently cost about $300,000/ton ($130/pound) to produce using methods available today. Using the new method, the researchers estimate that it would cost just $2,000/ton to produce CNTs—less than 1% of current production costs. The researchers hope that this large profit potential will make the technology seem like an obvious choice. Since CNTs are about 10,000 times more valuable than carbon tax credits (which are roughly $30/ton), the researchers predict that CNT production will offer a greater incentive for the energy industry to reduce carbon emissions than carbon tax credits offer.

Applied Energy Technologies (AET) announced that it has completed a 5MW solar installation project with Rosendin Construction Puerto Rico, in Juncos, Puerto Rico. The modules added to the project are Hanwha Q Cells 300W. The installation is expected to generate power to a Medtronic Pharmaceuticals site.

Applied Energy Technologies (AET) announced that it has completed a 5MW solar installation project with Rosendin Construction Puerto Rico, in Juncos, Puerto Rico. The modules added to the project are Hanwha Q Cells 300W. The installation is expected to generate power to a Medtronic Pharmaceuticals site.